Italian Pilsner Brew day

Today I am cover the process of my most recent brew day from start to finish. I hope you enjoy it.

Malt crusher/mill, can be hand or drill operated. We do not grind the malt, we crush it. Basically the husk is broken and the grain is crushed into 3-4 pieces. Of course part of that process is the dust. Its a happy medium. Too large or particles and your wort will be weak. Too fine and it will become nearly impossible to settle out all the proteins, thus a cloudy beer. If you’re making a hefeweizen or some IPA’s you’re fine but otherwise not. Too fine also can lead to a stuck mash ig you’re using a recirculating pump in a 3 kettle system or something like an Anvil Foundry All in One system.

The milling roll: Two usually stainless steel knurled rolls. One is moveable to facilitate crush size, the other is not. The one with the axle sticking out is powered by hand crank or drill.

This is the crush you want, not too fine not too course.

A scale is a necessity, I bought one of the big box name brand kitchen scales, it was frustrating. Weighs were inaccurate and nowhere close to where they needed to be. I was using a ammunition reloading beam scale prior to buying this scale. The beam scale is accurate to 1/10th of a grain. While not needing that kind of accuracy you have to be close. For those that do not know much about ammuntion - weight is deathly critical. You work in these 1/0 grain incriments as more can result in disaster and not enough can result in the bullet not flying acurately or worse not coming out the barrel.

A refractometer instantly reads gravity, in Brix, of unfermented wort or fruit juice by measuring the degree that light passing through the sample is bent. These are used when brewing anything. I even use mine to measure the sugar in my pasture grass. Sugars are carbs and cattle grow best with higher carb grass.

This brew came in at 1.045 starting gravity, I was shooting for 1.05 so off a 1/2 point. A little frustrating but not enough to really matter. The OG ( Origninal gravity ) reading is taken once you have the wort cooled to yeast pitching temperature.

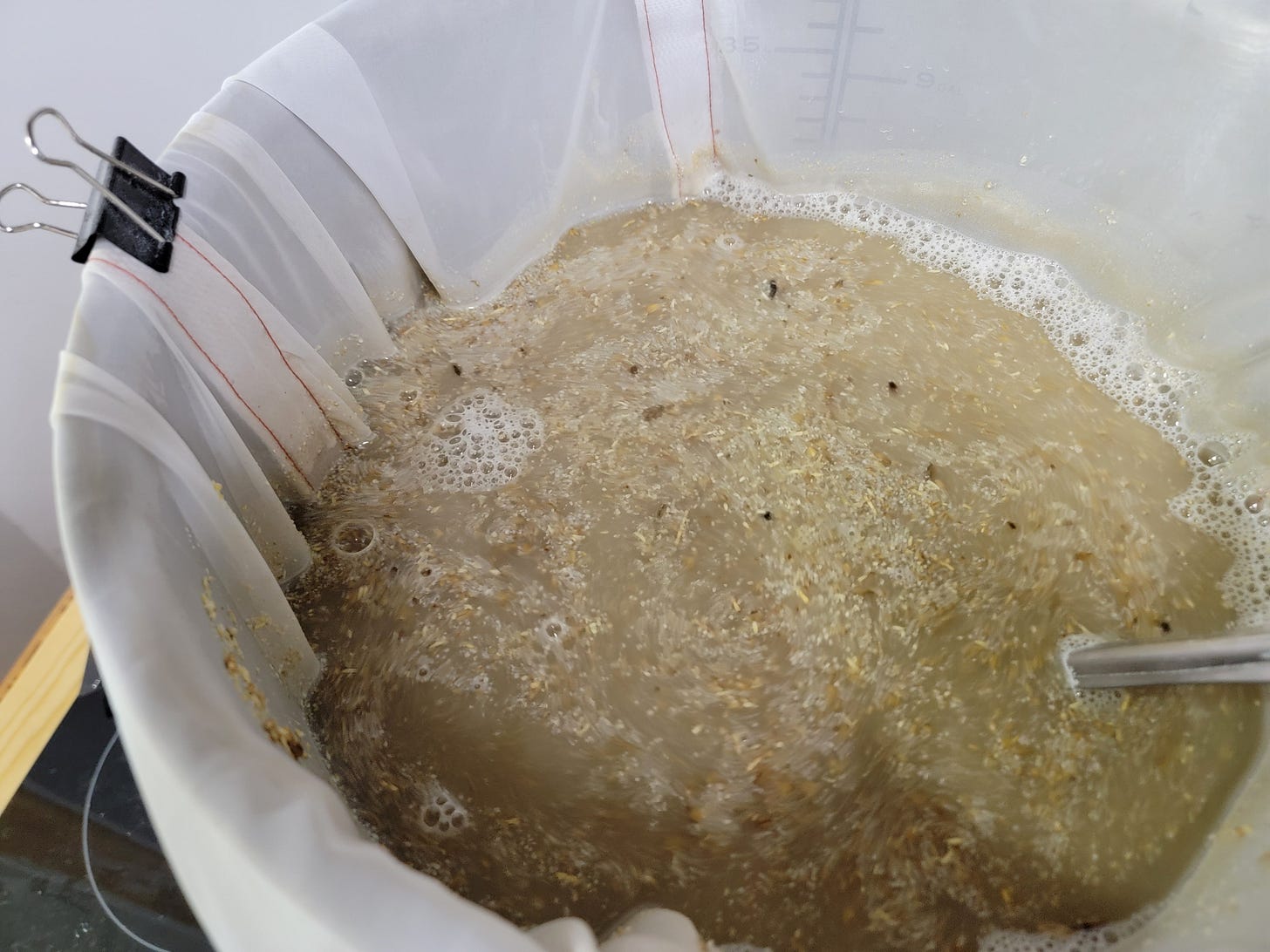

60 minute boil process This is necessary to boil down the water amount but also to bring out the bittering and other flavors of the hops.

One side hooks up to a hose from your faucet bringin cool water, the other side hooks up to a hose to a sink or drain as it takes away the hot water from the exhange. This is a closed loop no outside water is put in the wort. This is dropped in 10 minutes left in the boil to sterilize it.

Cooling takes about 20 minutes - from boiling to about 10 degrees above the incoming water. Mine is around 50-55 degrees so 65 is my done temperature.

PH is important in brewing. An aciditic ph helps extract the sugars. When brewing beer you want a ph of 5.2-5.6. This readin is take 10 minutes after the boil starts. I draw a small amount of wort cool to room temperature and take the reading. Mine came in at 5.5 so no corrections are necessary. A high ph requires lactic acid or citric acid - a little bit at a time. You can always add but never take it out. If the ph is low you add baking soda. I have found 3-4 oz of acidulated malt seems to bring me right in the range of 5.2-5.5.

Magnets are put in with the hops so at day 5 I can dry hop the brew. Dry hopping extracts the flavor of the hops without all the bitterness brought in by the boil.

The magnets to the right hold the hop bag at day 5 I will pull these off and let the hop bag fall into the wort. After 5 more days its ready to keg.

The “S” shaped thing is an air lock I fill mine with vodka. This releases the pressure from the yeast working over the sugars and turning them into alcohol. CO 2 is heavier than air so as the yeast starts working it pushed the air out after awhile and only CO2 is left. CO 2 is a hostile environment for bacteria so this protect the beer from foreign bacteria that can spoil the beer.

The black ring is what is unique about Anvils brew in a kettle system. It seals the brew kettle so no oxygen gets inside the vessel.

That’s it for now. I brewed this on Sunday so Friday evening I will drop the hops and 4-5 days later keg the beer. I will show that process in the future and give a critical review of the beer, or as critical as I can….